Key Takeaways

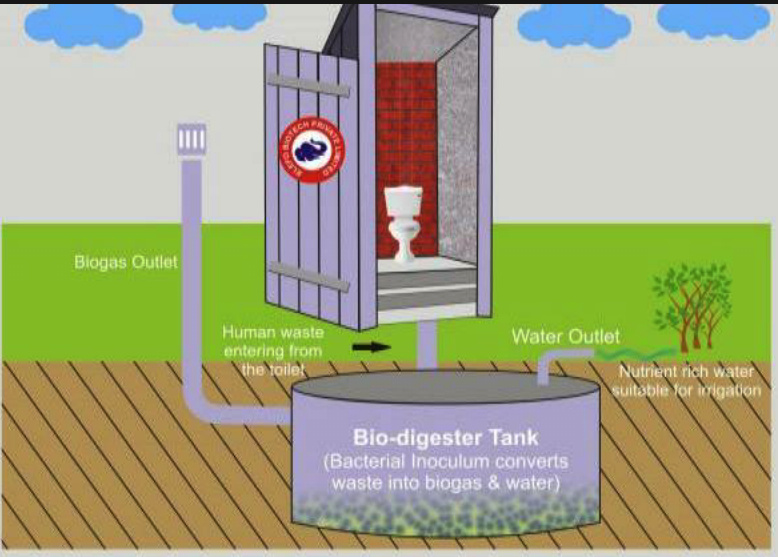

- Biodigester systems transform human waste into valuable resources like methane gas and nutrient-rich fertilizer through anaerobic digestion.

- These systems offer a sustainable solution to the global sanitation crisis, especially in areas lacking proper waste management infrastructure.

- Various biodigester designs are available to suit different settings, from rural communities to urban environments.

- Biodigesters provide multiple benefits: reducing pathogen spread by up to 99%, eliminating odors, and creating renewable energy.

- Organic Biotech offers specialized biodigester technology that requires minimal maintenance while maximizing resource recovery.

How Biodigesters Transform Human Waste into Resources

Human waste doesn’t have to be just waste. Through the remarkable process of anaerobic digestion, biodigester systems can transform what was once considered a disposal problem into valuable resources. These systems harness naturally occurring microorganisms to break down organic matter in the absence of oxygen, producing biogas (primarily methane) and nutrient-rich effluent that can serve as fertilizer.

The beauty of biodigester technology lies in its elegant simplicity and circular approach. Rather than treating human waste as something to discard, these systems recognize its potential as an energy source and soil amendment. A well-designed biodigester can reduce pathogen levels by up to 99%, eliminate unpleasant odors, and create renewable energy that can be used for cooking, heating, or even electricity generation. This transformation represents a paradigm shift in how we view sanitation – from a linear disposal model to a circular resource recovery system.

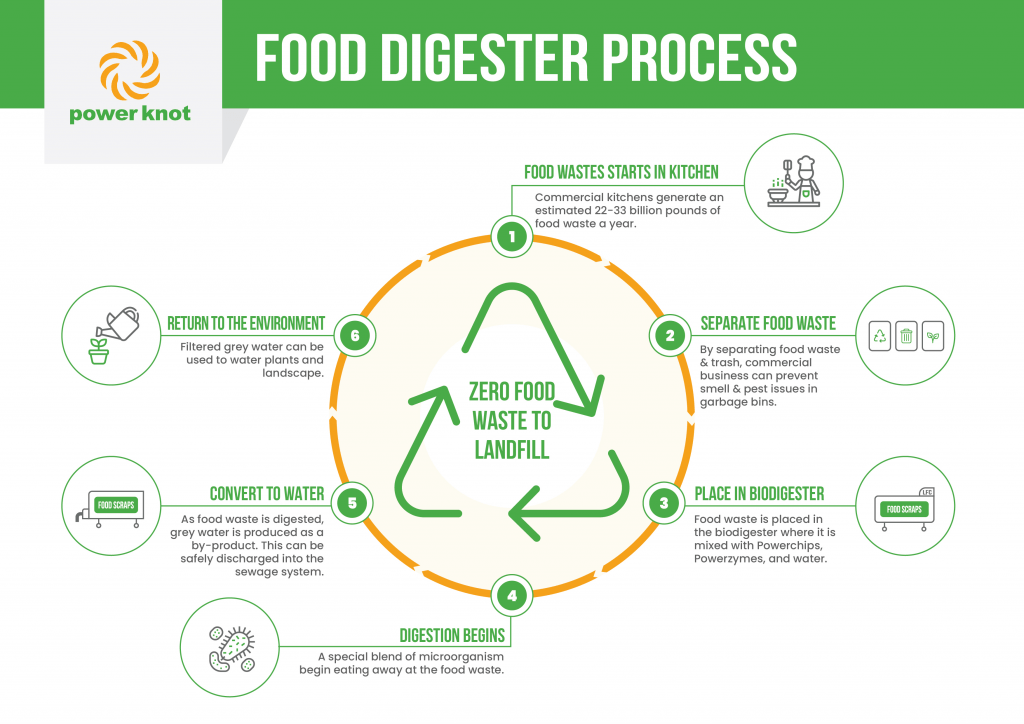

The process begins when human waste enters the digester chamber, where specific bacteria break down complex organic compounds. Through multiple stages of microbial activity, the waste is converted into biogas and a liquid slurry. The gas rises to the top of the chamber where it can be collected, while the processed effluent exits as a stabilized, nutrient-rich liquid that can safely nourish plants when applied to soil. This closed-loop system exemplifies sustainable waste management in action.

“Biodigesters represent one of the most promising technologies for addressing both sanitation needs and resource recovery in a single integrated system. They transform what was once considered waste into valuable resources while helping protect public health and the environment.” – Sustainable Sanitation Alliance

“How Microorganisms work in Biodigesters …” from powerknot.com and used with no modifications.

The Sanitation Crisis: Why We Need Better Solutions

Globally, over 2 billion people lack access to safely managed sanitation services, leading to widespread environmental contamination and serious public health threats. Untreated human waste introduces pathogens and nutrients into water systems, causing disease outbreaks and environmental degradation through algal blooms and ecosystem disruption. The sanitation crisis disproportionately affects those in developing regions, particularly in rural areas where conventional sewage infrastructure is often economically unfeasible.

Traditional approaches to human waste management typically rely on water-intensive, centralized systems that require extensive infrastructure and ongoing maintenance. In many parts of the world, these conventional solutions are neither affordable nor practical. Even in developed regions, aging sewage systems face mounting challenges from population growth, climate change impacts, and increasingly stringent environmental regulations. The limitations of conventional systems highlight the urgent need for innovative, decentralized solutions that can function effectively across diverse contexts while promoting resource recovery rather than mere waste disposal.

What Are Biodigester Systems and How Do They Work?

Biodigester systems are engineered environments designed to optimize the natural process of anaerobic digestion. At their core, these systems consist of sealed chambers where organic matter decomposes in the absence of oxygen. When human waste enters a biodigester, it undergoes a series of biological transformations facilitated by different groups of microorganisms. The process typically occurs in four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis – culminating in the production of biogas and stabilized effluent.

Unlike conventional septic systems that primarily focus on settling and filtration, biodigesters actively promote microbial decomposition to transform waste. Modern biodigester designs incorporate features that optimize conditions for the microbial communities responsible for decomposition. These may include temperature management systems, mixing mechanisms, and gas collection apparatus. The entire process occurs in a sealed environment, containing odors and preventing the release of pathogens into the surrounding environment while capturing valuable biogas.

The Science Behind Anaerobic Digestion

Anaerobic digestion begins with hydrolysis, where complex organic polymers like proteins, carbohydrates, and fats break down into simpler compounds such as amino acids, sugars, and fatty acids. Next comes acidogenesis, during which acidogenic bacteria convert these simple compounds into volatile fatty acids, alcohols, carbon dioxide, and hydrogen. The third stage, acetogenesis, sees the conversion of these intermediate products into acetic acid, carbon dioxide, and hydrogen – the direct precursors to methane. Finally, during methanogenesis, specialized archaebacteria convert these compounds into methane and carbon dioxide, completing the biogas formation process. This biological cascade happens naturally whenever organic matter decomposes without oxygen, but biodigester systems optimize conditions to maximize efficiency and resource recovery.

Key Components of a Biodigester System

A complete biodigester system for human waste typically consists of several critical components working in harmony. The inlet provides the entry point for waste material, often connected directly to toilets or through a collection system. The main digestion chamber, or reactor, provides the anaerobic environment where microbial decomposition occurs. Many systems include a mixing mechanism to ensure proper contact between microbes and waste material. Gas collection and storage systems capture the produced biogas, usually in the upper portion of the digester or in separate storage units. An outlet system allows for the removal of processed effluent, which can be directed to secondary treatment or used as fertilizer depending on local regulations and needs. Some advanced systems also incorporate temperature control mechanisms, monitoring equipment, and even gas purification systems to enhance performance and usability of the end products.

“Bio Digester Toilet Over Septic Tanks …” from www.nairaland.com and used with no modifications.

Types of Biodigester Systems for Human Waste

Biodigester systems come in various designs, each with unique advantages suited to different contexts and needs. The selection of an appropriate biodigester design depends on factors such as climate, available space, installation budget, technical expertise for maintenance, and the volume of waste to be processed. Some systems excel in rural settings with ample space, while others are specifically engineered for urban environments where space constraints present significant challenges.

The evolution of biodigester technology has led to increasingly efficient and user-friendly designs. Modern innovations include prefabricated units that simplify installation, systems optimized for colder climates, and compact designs suitable for individual households. Each type represents a different approach to the same fundamental process of anaerobic digestion, with variations in construction materials, chamber configuration, gas collection methods, and effluent management systems.

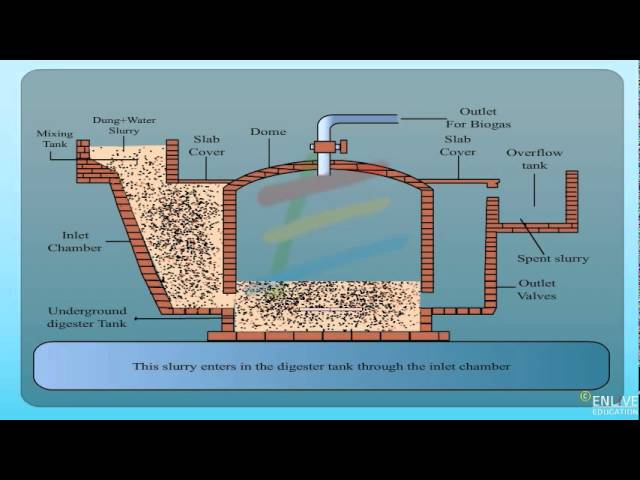

1. Fixed-Dome Biodigesters

Fixed-dome biodigesters feature a permanent, immovable dome structure typically constructed of brick, concrete, or fiberglass. These systems operate on a displacement principle where incoming waste pushes processed slurry out through an outlet pipe. The dome serves as both digestion chamber and gas storage unit, with gas pressure increasing as biogas accumulates in the upper portion. This design is known for its durability, with well-constructed units potentially lasting 20-30 years with minimal maintenance. Fixed-dome biodigesters are particularly popular in community-scale installations due to their reliability and longevity, though they require skilled construction to ensure the dome remains gas-tight. For a deeper understanding of how these systems work, you can explore what an anaerobic digester is and its benefits.

“Fixed dome type biogas plant – YouTube” from www.youtube.com and used with no modifications.

2. Floating-Drum Biodigesters

Floating-drum systems consist of an underground digester chamber with a movable gas-collection drum that rises and falls depending on the volume of gas stored. The floating drum provides visible feedback about gas production and maintains consistent gas pressure regardless of the volume stored. These systems are relatively simple to operate and maintain, with the drum’s movement providing a clear visual indicator of gas production levels. However, the metal drum is susceptible to corrosion over time, requiring periodic maintenance or replacement. Floating-drum designs are particularly well-suited to educational settings or situations where users benefit from the visual feedback of gas production. For a broader perspective on biogas systems, check out this article about biogas energy in Denmark.

“Bio-Digester at best price in Nashik by …” from www.indiamart.com and used with no modifications.

3. Tubular/Bag Biodigesters

Tubular biodigesters consist of a long, cylindrical bag made from durable, flexible materials like PVC or polyethylene. These low-cost systems are easily transported and installed, making them ideal for remote locations or as temporary solutions. The elongated design creates a natural flow path that helps separate different stages of the digestion process. While tubular systems require less investment and technical expertise to install than other designs, they typically have shorter lifespans (5-10 years) and may be more vulnerable to physical damage. Their simplicity and affordability make them particularly valuable for small-scale applications, especially in resource-limited settings where cost is a primary concern.

“Polyethylene tube digester – Appropedia …” from www.appropedia.org and used with no modifications.

4. Prefabricated Biodigester Units

Prefabricated biodigesters come as ready-to-install systems manufactured from materials like fiberglass, plastic, or stainless steel. These units arrive with all components integrated, significantly reducing installation time and complexity. Many include advanced features such as automatic mixing, temperature control, and monitoring systems that optimize performance. The standardized production process ensures quality control and predictable performance across installations. While typically more expensive initially than site-built alternatives, prefabricated systems often prove cost-effective when considering the reduced installation time, consistent performance, and lower risk of construction defects. Organic Biotech offers specialized prefabricated biodigester units designed specifically for human waste processing with minimal maintenance requirements.

“FRP Prefabricated Bio Digester Tanks …” from www.indiamart.com and used with no modifications.

5. Bio-Toilet Systems

Bio-toilet systems integrate biodigester technology directly with toilet fixtures, creating a comprehensive sanitation solution. These systems can range from simple designs for individual households to sophisticated units for public facilities. Most bio-toilet systems require minimal or no water for flushing, addressing water conservation needs alongside waste management. The compact design makes them suitable for installation in locations where space is limited or where conventional plumbing is impractical. Many modern bio-toilet designs include features to enhance user experiences, such as odour control systems and aesthetic designs that resemble conventional toilets, increasing acceptance and adoption rates.

“Bio-Toilet kit: HomeBiogas 2 + Toilet …” from www.homebiogas.com and used with no modifications.

Benefits of Using Biodigesters for Human Waste

Biodigester systems offer a comprehensive solution to human waste management challenges, delivering multiple benefits across environmental, social, and economic dimensions. Unlike conventional waste treatment approaches that focus primarily on disposal, biodigesters transform waste into valuable resources while addressing public health concerns. This multifaceted approach makes them particularly valuable in contexts where integrated solutions to sanitation, energy, and agricultural challenges are needed.

The decentralized nature of biodigester systems provides flexibility in implementation, allowing for gradual scaling from household to community levels without requiring massive infrastructure investments. This adaptability makes them suitable for diverse contexts from dense urban informal settlements to remote rural communities. Additionally, biodigester technology can be implemented with varying levels of technical sophistication, from simple manual systems to highly automated installations with remote monitoring capabilities.

Environmental Advantages

Biodigesters deliver significant environmental benefits by preventing the contamination of water sources with untreated human waste. By containing and processing waste in a sealed environment, they reduce pathogen spread and nutrient pollution that would otherwise contribute to waterway eutrophication and ecosystem damage. The captured methane is used productively rather than released into the atmosphere, mitigating the greenhouse gas impact that would occur from conventional waste decomposition. A single household biodigester can prevent the equivalent of 4-5 tons of CO₂ emissions annually when the captured methane replaces fossil fuels for cooking or heating.

Additionally, biodigesters promote resource conservation by reducing water consumption compared to flush-based sanitation systems. The production of nutrient-rich fertilizer also helps close the nutrient cycle, returning valuable elements like nitrogen, phosphorus, and potassium to agricultural soils rather than allowing them to become pollutants. This circular approach supports soil health and can reduce dependence on synthetic fertilizers, which require significant energy inputs to produce and can contribute to environmental degradation when overused.

Health Improvements

Proper waste management through biodigester systems significantly reduces exposure to pathogens that cause serious diseases like cholera, typhoid, and intestinal parasites. The anaerobic digestion process naturally destroys up to 99% of pathogens present in human waste, creating a crucial barrier in disease transmission pathways. This pathogen reduction is particularly valuable in densely populated areas where sanitation-related disease outbreaks can spread rapidly. Additionally, by containing waste and eliminating open defecation, biodigesters help reduce vector-borne disease transmission by limiting insect breeding grounds.

Economic Benefits

Biodigester systems generate economic value through multiple channels, transforming what was once a disposal cost into a potential revenue stream. The biogas produced can replace purchased fuels for cooking, heating, or even electricity generation, creating immediate household savings. For example, a family using biogas for cooking typically saves $10-30 monthly on fuel purchases. The nutrient-rich effluent serves as an effective fertilizer, improving agricultural yields while reducing expenditure on commercial fertilizers. Beyond these direct benefits, communities with improved sanitation through biodigester implementation typically experience reduced healthcare costs and fewer lost work days due to sanitation-related illnesses, creating broader economic benefits that compound over time.

Valuable Outputs from Biodigester Systems

Biodigester systems transform human waste into two primary valuable outputs: biogas and nutrient-rich effluent. Unlike traditional waste disposal methods that treat human waste as a liability, biodigesters recognize its potential as a resource. This fundamental shift in perspective aligns perfectly with circular economy principles, where waste from one process becomes input for another. The dual outputs address two critical needs—sustainable energy and soil fertility—from a single waste stream.

The efficient recovery of these resources depends on proper system design, operation, and maintenance. Temperature, retention time, and feedstock composition all influence the quantity and quality of outputs. Modern biodigester designs increasingly incorporate features to optimize these parameters, maximizing resource recovery while minimizing manual intervention requirements.

Biogas Production and Uses

Biogas produced by biodigesters typically contains 50-70% methane, 30-45% carbon dioxide, and small amounts of other gases. This composition makes it suitable for various applications including cooking, heating, lighting, and even electricity generation. For cooking applications, biogas performs similarly to natural gas, with a typical family-sized biodigester producing enough gas to meet most household cooking needs. The flame produced burns cleanly with minimal smoke, offering significant health advantages over solid fuels like wood or charcoal that cause indoor air pollution.

For lighting, biogas can power special biogas lamps that function similarly to kerosene lamps but without the harmful emissions. When electricity generation is desired, biogas can fuel specially adapted generators or combined heat and power systems. While the raw biogas requires minimal processing for direct combustion applications like cooking, more advanced uses like vehicle fuel or natural gas grid injection require additional purification steps to remove carbon dioxide and trace contaminants. This versatility makes biogas an exceptionally valuable output that can be adapted to local needs and technical capabilities.

Nutrient-Rich Fertilizer

The liquid effluent from biodigesters contains essential plant nutrients including nitrogen, phosphorus, and potassium in forms that are readily available to plants. Unlike raw human waste, the digested effluent has significantly reduced pathogen levels and objectionable odors, making it safer and more pleasant to handle. The digestion process also breaks down complex organic compounds, releasing nutrients that were previously bound in forms unavailable to plants. This nutrient-rich slurry can be applied directly to fields or gardens, either through irrigation systems or manual application.

Studies have shown that crops grown with biodigester effluent often show yield increases of 10-30% compared to untreated plots. Beyond the major nutrients, the effluent also contains valuable micronutrients and organic matter that contribute to long-term soil health and fertility. Some advanced biodigester systems include additional processing for the effluent, such as solid-liquid separation to create both liquid fertilizer and compost material, offering even greater flexibility in agricultural applications.

![]()

“N Fertiliser Value and C Mineralisation …” from link.springer.com and used with no modifications.

Installation and Setup Guidelines

Successful biodigester installation begins with thorough planning and site assessment. The process requires consideration of local regulations, climate conditions, waste volume, available space, and intended use of outputs. Many regions have specific requirements regarding human waste treatment systems, particularly concerning effluent disposal and monitoring. Consulting with local authorities and sanitation experts early in the planning process can prevent regulatory complications later.

Professional installation is recommended for most biodigester systems, especially those processing human waste, to ensure proper function and safety. However, some simpler designs can be implemented using local materials and labor with appropriate guidance. Regardless of the installation approach, proper training for system operators is essential for long-term success.

Site Selection Factors

Ideal biodigester placement balances convenience, safety, and operational efficiency. The system should be reasonably close to waste sources to minimize transport requirements, yet maintain appropriate distance from living spaces, particularly if manual feeding is required. Sites should provide protection from extreme temperatures while ensuring adequate access for maintenance activities. Ground stability is crucial, as biodigesters contain significant weight when filled, and some designs require excavation. Proper drainage around the site prevents water accumulation that could damage the system or create unsanitary conditions.

Access to water is another important consideration, as most systems require some water for initial setup and ongoing operation. For systems intended to produce biogas for household use, proximity to the point of use minimizes the complexity and cost of gas transport. If the effluent will be used for agriculture, convenient access to fields or gardens simplifies application. Finally, community acceptance and user preferences should inform site selection, particularly for shared or community-scale systems.

Size and Capacity Planning

Proper sizing ensures that the biodigester effectively processes all incoming waste while producing useful quantities of biogas and fertilizer. The primary sizing factor is the daily volume of waste to be processed, typically calculated based on the number of users and their waste production patterns. For human waste, a general guideline is 1-2 liters of digester volume per person served, though this varies with system design and climate. Colder climates require larger digesters to compensate for slower microbial activity, sometimes 2-3 times the volume needed in tropical regions.

Beyond the digestion chamber itself, space must be allocated for gas storage, which typically requires 40-60% of the daily gas production volume. Systems should include some excess capacity to accommodate variations in waste production and to provide flexibility for future expansion. Some designs also incorporate separate pre-treatment or post-treatment components that require additional space. Professional designers can provide specific sizing recommendations based on local conditions and intended use patterns.

Step-by-Step Installation Process

The installation process varies significantly depending on the biodigester type, but typically includes site preparation, construction or placement of the digestion chamber, installation of inlet and outlet systems, and setup of gas collection infrastructure. For underground systems, excavation must account for the full dimensions of the digester plus working space for construction. The chamber must be made watertight and gastight, which may involve special sealants or construction techniques. Some systems require special foundations or reinforcement to support the weight and pressure of the filled digester.

After constructing the main components, inlet pipes from toilets or waste collection points are connected to the digestion chamber. Outlet systems for effluent management are installed, which may include overflow protection and distribution systems for agricultural application. Gas collection systems require careful installation to ensure safety, with proper pressure regulation, moisture traps, and in some cases, hydrogen sulfide filters to protect end-use appliances. Initial filling typically includes “seeding” the digester with active microbial cultures from existing systems or animal manure to jumpstart the digestion process. Finally, comprehensive testing ensures all components function properly before the system enters regular operation.

Maintenance Requirements for Optimal Performance

Proper maintenance ensures biodigester longevity and consistent output quality. Unlike conventional septic systems that may require complete pumping every few years, well-designed biodigesters process waste continuously with minimal solids accumulation. However, they do require regular attention to maintain optimal microbial activity and prevent system issues. Developing a maintenance schedule based on the specific system design and local conditions helps ensure these critical tasks aren’t overlooked.

Maintenance complexity varies significantly between systems. Simple fixed-dome or tubular digesters may require only basic monitoring and occasional cleaning of inlet and outlet pipes. More sophisticated systems with mechanical components like mixers, pumps, or heating elements require additional technical maintenance. Training operators in both routine maintenance and troubleshooting ensures small issues can be addressed before they develop into system failures.

Daily and Weekly Checks

Regular monitoring forms the foundation of effective biodigester maintenance. Daily visual inspection of inlet and outlet areas ensures waste is flowing properly without blockages or backups. Checking gas pressure through gauges or observing gas storage systems helps confirm that gas production remains consistent. For systems with manual feeding, maintaining proper feeding schedules and waste-to-water ratios is essential for stable operation. Users should also be alert to any unusual odors, which might indicate imbalances in the digestion process.

Weekly maintenance typically includes more thorough inspection of all accessible components and connections. Gas pipes should be checked for leaks using soapy water to detect bubbles at connection points. Any condensate traps in the gas line should be emptied to prevent blockages. For systems with effluent used in agriculture, irrigation lines or distribution systems should be checked for clogs or damage. These regular checks allow early detection of developing problems, often preventing more serious system failures.

Monthly Maintenance Tasks

Monthly maintenance focuses on more comprehensive system checks and preventative measures. Inlet and outlet pipes may require cleaning to remove accumulated solids that could restrict flow. Gas filters, particularly hydrogen sulfide scrubbers if present, should be inspected and replaced or regenerated as needed. Any mechanical components like mixers should undergo more thorough inspection and lubrication according to manufacturer specifications. For systems with separate gas storage, checking pressure relief valves and storage integrity becomes especially important for safety reasons.

Seasonal maintenance considerations are also important, particularly in regions with significant temperature variations. In colder months, insulation may need inspection or reinforcement to maintain adequate digestion temperatures. Some systems may require adjustments to feeding rates or dilution ratios based on seasonal changes in microbial activity. For systems using the effluent in agriculture, seasonal crop rotations may necessitate changes in effluent application patterns or storage.

Troubleshooting Common Issues

Even well-maintained biodigesters occasionally encounter operational issues. Decreased gas production often indicates problems with microbial activity, potentially due to temperature fluctuations, pH imbalances, or introduction of antimicrobial substances like certain cleaning chemicals. Corrective measures may include adjusting feeding patterns, adding buffering agents to stabilize pH, or in severe cases, partially reseeding the system with active microbial cultures. Excessive foaming can occur when certain types of waste create surfactants during decomposition, and may require anti-foaming agents or adjustments to feeding practices.

Blockages in inlet or outlet pipes typically result from inappropriate materials entering the system or inadequate pre-treatment. Regular cleaning and user education about appropriate inputs can prevent most blockages. Gas leaks present both functionality and safety concerns, requiring immediate attention to locate and repair the source. For systems with more complex components like pumps or heating elements, manufacturer troubleshooting guides provide specific diagnostic and repair procedures. Developing a relationship with local technical support resources ensures access to expertise for issues beyond basic troubleshooting.

Rural Community Success Stories

In rural Rwanda, the implementation of community-scale biodigesters has transformed sanitation practices while providing valuable cooking fuel. One notable project in the Bugesera District connected 50 households to a centralized biodigester that processes human waste from improved latrines. The system generates enough biogas to meet 70% of the community’s cooking needs, significantly reducing reliance on collected firewood and the associated deforestation. Women in the community report saving 2-3 hours daily previously spent gathering cooking fuel, time now dedicated to educational and income-generating activities. Additionally, the nutrient-rich effluent has increased crop yields by approximately 25% in community garden plots, improving both nutrition and household incomes.

Urban Applications

Urban biodigester applications demonstrate the technology’s adaptability to space-constrained environments. In Nairobi, Kenya, a multi-story apartment complex integrated a compact prefabricated biodigester system in its basement level, processing waste from 200 residents. The system’s modular design allowed for installation in limited space, while advanced odor control features ensure resident acceptance. The generated biogas powers a generator that provides backup electricity for common area lighting and water pumping during frequent grid outages. This application demonstrates how biodigesters can function effectively even in dense urban settings, providing waste management solutions while contributing to energy resilience for critical infrastructure.

Cost Considerations and Return on Investment

The financial aspects of biodigester implementation involve balancing initial investment against long-term benefits and operational savings. While upfront costs may exceed those of simpler waste disposal methods, the ongoing value generated through biogas production, fertilizer creation, and reduced environmental impact typically delivers favorable long-term economics. A comprehensive financial analysis should consider both direct monetary returns (like fuel savings) and indirect benefits such as improved health outcomes, environmental protection, and enhanced agricultural productivity. For many implementations, particularly in areas with limited existing infrastructure, biodigesters represent not just an environmentally sound choice but also a financially prudent long-term investment.

Initial Setup Expenses

Initial biodigester costs vary significantly based on system type, size, materials, and local conditions. Small household systems using local materials may cost as little as $300-500, while prefabricated units with advanced features typically range from $1,000-5,000 for family-sized installations. Community-scale systems serving 50-100 people generally require investments of $5,000-20,000 depending on design complexity and local material costs. Installation expenses, including excavation, plumbing connections, and gas piping, typically add 30-50% to equipment costs unless significant community labor contributions offset these expenses. Many implementations now benefit from financing mechanisms like microloans, subsidies from sanitation programs, or carbon credit funding that can significantly reduce initial cash outlays for adopters.

Ongoing Operational Costs

Well-designed biodigester systems require minimal ongoing financial inputs, with most operational costs relating to occasional maintenance rather than regular consumables or energy inputs. Basic maintenance supplies like pipe cleaners, sealants for minor repairs, and replacement parts for wear items like gas valves typically cost $20-50 annually for household systems. Systems with mechanical components like mixers or pumps may require more significant maintenance, with annual costs typically ranging from 2-5% of the initial system cost. Labor requirements vary widely, from just 5-10 minutes daily for simple manual-feed systems to nearly automated operation for some advanced designs. For farms, comparing biogas vs solar vs wind options can help in choosing the most cost-effective energy solution.

Training represents another operational consideration, particularly when systems serve multiple users or when operator turnover occurs. Initial comprehensive training ensures proper operation, while periodic refresher sessions maintain good practices over time. Some implementation programs build ongoing technical support into their models, providing access to expertise when issues exceed local troubleshooting capabilities.

Financial Benefits and Savings

The economic returns from biodigester systems derive primarily from the value of outputs produced and costs avoided. Biogas typically replaces purchased fuels like LPG, kerosene, or charcoal, with savings of $10-30 monthly for an average household based on local fuel prices. The fertilizer value of effluent ranges from $5-15 monthly for household systems when compared to equivalent commercial fertilizers. Additional economic benefits include reduced expenses for waste management services, decreased healthcare costs from sanitation-related illnesses, and potential income from carbon credits in some implementations. For agricultural operations, improved crop yields from fertilizer application can significantly enhance income, sometimes increasing annual revenues by 15-30% for small-scale farmers.

Make the Switch to Sustainable Waste Management Today

Human waste management doesn’t have to be a burden on our environment or communities. Biodigester systems offer a practical, sustainable approach that transforms this challenge into an opportunity for resource generation while protecting public health and ecosystems. Whether you’re considering solutions for an individual household, a community project, or a larger institutional application, biodigester technology provides adaptable options that can be tailored to your specific context and needs. By closing the loop on waste management, you contribute to multiple sustainability goals simultaneously: sanitation improvement, renewable energy production, and soil fertility enhancement.

The transition to biodigester-based waste management becomes increasingly accessible as the technology matures and implementation expertise grows. Many regions now have experienced installers, supportive regulatory frameworks, and financing mechanisms that facilitate adoption. The growing community of biodigester users provides valuable peer learning opportunities and shared experiences that can inform your implementation. When properly designed, installed, and maintained, these systems deliver years of reliable service with minimal intervention while providing valuable outputs that offset the initial investment.

For more information on biodigester systems tailored to your specific needs, contact Organic Biotech today. Our expert team can guide you through the selection, installation, and operation process to ensure your biodigester system delivers maximum benefits with minimum hassle.

Frequently Asked Questions

Biodigester systems represent a significant shift from conventional waste management approaches, naturally raising questions about their operation, benefits, and practical considerations. The following frequently asked questions address common concerns and provide essential information for those considering biodigester implementation. These insights reflect both technical understanding and practical experience from existing installations across diverse settings.

Understanding these fundamentals helps potential adopters make informed decisions about whether biodigester technology aligns with their specific needs and capabilities. For more detailed information relevant to your particular situation, consulting with experienced biodigester designers or implementers provides valuable customized guidance.

How long does it take for a biodigester to start producing biogas?

New biodigester systems typically require 2-4 weeks to begin producing usable quantities of biogas, with production gradually increasing as microbial communities establish themselves. This startup period can be shortened by “seeding” the digester with active microbial cultures from existing systems or with animal manure, which introduces beneficial bacteria that accelerate the digestion process. Temperature significantly affects startup time, with systems in warmer climates (above 25°C/77°F) generally achieving full production more quickly than those in cooler environments. During this initial period, gas quality may fluctuate with higher carbon dioxide content, gradually improving as methanogenic bacteria populations stabilize. Users should plan alternative energy sources for this transition period until biogas production reaches reliable levels.

Are biodigesters safe to use near residential areas?

Properly designed and maintained biodigester systems pose minimal risk when installed near residential areas. The sealed anaerobic environment contains odors that would otherwise cause nuisance, actually improving air quality compared to alternative waste management approaches. Modern designs incorporate multiple safety features, including pressure relief valves that prevent excessive gas buildup, water traps that prevent flame backflow, and in some cases, gas sensors that detect leaks. The biogas produced contains hydrogen sulfide which has a distinctive “rotten egg” smell even in tiny concentrations, making small leaks easily detectable before they pose any safety hazard. For additional peace of mind, maintaining appropriate clearances from open flames and installing simple gas detection systems provides extra layers of protection for residential installations.

Can biodigesters work in cold climates?

Biodigesters can function effectively in cold climates with appropriate design modifications and operational adjustments. Since the anaerobic digestion process slows significantly at temperatures below 15°C (59°F), cold climate installations typically incorporate insulation, passive solar heating, or active heating systems to maintain optimal internal temperatures. Underground installation provides natural insulation, with deeper placement in colder regions to take advantage of stable ground temperatures. Some designs use greenhouse enclosures or solar collectors to capture heat during daylight hours. For extremely cold environments, systems may include heat exchangers that recirculate a portion of the biogas energy to maintain digester temperature. These adaptations generally increase initial system costs but remain economically viable through extended seasonal operation and consistent gas production.

How much maintenance do biodigesters require?

Maintenance requirements vary by system design but are generally minimal for well-constructed biodigesters. Simple fixed-dome or tubular designs may require just 15-30 minutes weekly for basic inspection and occasional pipe cleaning. More complex systems with mechanical components like mixers, pumps, or heating elements typically demand 2-4 hours monthly for more thorough maintenance procedures. Unlike conventional septic systems, properly functioning biodigesters continuously process solids, eliminating the need for periodic pumping in most cases. The most common maintenance tasks include clearing inlet and outlet pipes, checking gas connections for leaks, emptying condensate traps, and inspecting pressure relief valves – all relatively simple procedures that can be performed with basic tools and minimal technical training.

Seasonal maintenance may involve additional tasks like adjusting feeding rates during temperature fluctuations or reinforcing insulation before cold weather periods. Most maintenance issues can be prevented through proper operator training and regular system checks, making biodigesters a low-maintenance option for sustainable waste management.

What happens to pathogens in human waste during the digestion process?

The anaerobic digestion process significantly reduces pathogen levels in human waste through multiple mechanisms. The combination of retention time, competition from beneficial microbes, and unfavorable environmental conditions inside the digester creates a hostile environment for most pathogens. Properly designed systems achieve 90-99% pathogen reduction, with elimination rates varying by organism type and system conditions. Bacteria like E. coli typically show 99% reduction in properly functioning systems, while more resistant parasites and helminth eggs may require longer retention times or secondary treatment for complete elimination. Temperature plays a crucial role in pathogen reduction, with thermophilic systems (operating above 45°C/113°F) achieving faster and more complete pathogen destruction than mesophilic systems operating at lower temperatures.