Thinking about the Anaerobic Digestion of Food Waste. Did you know that a single tonne of food waste processed in the right anaerobic digester can generate enough renewable energy to power an average home for several days—yet if mishandled, it can unleash invisible microplastics into our environment, threatening soil, water, and health?

With England’s councils racing to comply with the 2026 “Simpler Recycling” law, the nation stands at a crossroads: can we unlock the true energy potential of anaerobic digestion using food waste while avoiding the hidden costs of microplastic pollution?

This article gives you a comprehensive, easy-to-follow guide on the process, the looming risks, and the innovative solutions councils must choose to ensure a cleaner, greener future.

The Race Against Time and Microplastics: England’s 2026 Food Waste Deadline

April 2026 marks the deadline when all English councils must offer weekly food waste recycling under the Simpler Recycling initiative, part of the Environment Act 2021. The new legislation is designed to reduce landfill dependency, shrink the carbon footprint, and capture energy from what would otherwise be thrown away.

In practice, however, councils are operating under enormous pressure: they must rapidly scale up capacity, award contracts for the intake and processing of dramatically larger amounts of food waste, and do so while keeping costs (gate fees) as low as possible.

This high-stakes challenge is creating fierce competition among waste operators, each promising efficient, cost-effective solutions for handling organic waste.

The “Under the Radar” Microplastics Danger

But hidden within this race is a danger even more insidious than wasted resources: many conventional depackaging machines—the equipment designed to separate food from packaging before it enters anaerobic digesters—operate using aggressive shredding, crushing, or milling.

While such “brute force” pre-treatment grabs headlines for their speed or scale, they generate microplastics that contaminate both the digestate (the solid output applied to fields as fertilizer) and the liquid runoff entering water systems.

These minuscule plastics, along with heavy metals sometimes present in packaging, are virtually impossible to remove once released. As a result, local authorities and waste processors must now navigate not just the logistics of site work and cost control, but also the looming spectre of long-term environmental harm.

“Every tonne of food waste processed via anaerobic digestion can power a home for several days, but at what hidden cost to our soil and water?”

What You’ll Learn About Anaerobic Digestion Food Waste Processing

- How anaerobic digestion transforms food waste into renewable energy

- The risks of microplastic contamination in current food waste recycling practices

- Best practices for safe, efficient anaerobic digestion food waste management

- Key considerations for councils in contract awards before the 2026 deadline

Anaerobic Digestion Food Waste: How the Process Works

Understanding the Anaerobic Digestion Process

The anaerobic digestion of food waste is a natural process that breaks down organic matter in the absence of oxygen. Specialized anaerobic digesters—sealed tanks using carefully controlled conditions—transform food waste and other organics into biogas and rich, nutrient-laden digestate. This process is carried out in multiple stages: hydrolysis, acidogenesis, and methanogenesis.

- Definition and overview of anaerobic digestion food waste conversion: Anaerobic digestion is a closed-loop, waste recycling process that turns food waste, garden organics, and other organic material into biogas (primarily methane and carbon dioxide) and biofertiliser. It is an efficient alternative to landfilling and incineration, reducing greenhouse gas emissions and producing renewable energy for use on the national gas grid (or locally as vehicle fuel).

- Role of anaerobic digester equipment: Modern digesters employ temperature control, mechanical mixing, and automated feeding to optimize the breakdown of food waste. These tanks operate out of public view, quietly transforming discarded banana peels, spoiled meat, and other food scraps into valuable energy and fertilizer with minimal odours or emissions.

- Stages of the digestion process: First, in hydrolysis, enzymes break down large organic molecules into smaller soluble ones. Next, during acidogenesis, bacteria convert these to volatile fatty acids. Finally, methanogenesis transforms the acids into methane-rich biogas and carbon dioxide—plus digestate, a solid and liquid by-product perfect for enriching soils, provided it’s free from contaminants.

| Feature | Conventional (Brute-Force Shredding) | Advanced (Non-Destructive Separation) |

|---|---|---|

| Plastic Separation Quality | Shredded into microplastics mixed with food pulp | Packaging remains largely intact, separated cleanly |

| Digestate/Compost Purity | High risk of microplastic, heavy metal contamination | Low contamination, easier to certify for agricultural use |

| Plastic Recyclability/Recovery | Diminished; plastics lose recycling value | Intact packaging can be recycled or used for energy recovery |

| Environmental Impact | Potential pollution of soil and water, long-term legacy risk | Reduced pollution, supports closed-loop recycling |

| Compliance with Future Legislation | May fail microplastic compliance and agricultural digestate standards | Higher likelihood of compliance, future-proof |

Economic Pressures vs. Environmental Responsibility in Food Waste Recycling

Gate Fees, Contract Awards, and the Pursuit of Cost Efficiency

The economic imperative driving English councils in their waste recycling efforts is clear: secure low “gate fees” from private contractors to minimize public costs while maximizing service reach. As councils finalize multi-year deals for anaerobic digestion food waste, renewable power generation, and safe digestate outlets, they risk prioritizing short-term savings over environmental integrity.

Often, the lowest-bid contractors rely on legacy depackaging systems—systems that may deliver fast, large-scale throughput, but do so at the expense of environmental responsibility.

This relentless focus on immediate financial outcomes may be understandable given shrinking budgets and rising operational demands. Yet, experts warn that neglecting the quality of pre-treatment could saddle councils and communities with an invisible, toxic legacy.

Once microplastics and heavy metals are released into digestate and scattered across farmland, the costs of remediation—and the damage to public trust—may be heavy indeed. Ultimately, true cost efficiency in food waste management must account for the life-cycle impacts of waste processes, not just today’s bottom line.

The Overlooked Threat: Microplastics from Brute Force Depackaging

Traditional depackaging machines often use intense mechanical force to liberate food organics from containers. Unfortunately, such processes also rip, shred, or pulverize packaging, creating microplastics undetectable to the naked eye but pervasive in the pulp. When this contaminated food pulp is digested, the resulting biofertiliser—intended to rejuvenate agricultural land—is instead laced with persistent plastic residues.

- How traditional food waste depackaging creates microplastics: “Size reduction” depackagers, such as hammermills and shredders, indiscriminately tear apart packaging along with the food inside. This creates thousands of tiny plastic fragments per item, which mingle irreversibly with organic material.

- Impact of microplastics and heavy metals on soil and water quality: Studies reveal that micro- and nanoparticles pass through most (site work) screening processes and enter digestate or compost. When used as fertilizer, these microplastics accumulate in soil, leach into waterways, and become part of the aquatic and terrestrial food chains, threatening food security and ecosystem health for generations.

- Legislation and compliance considerations for waste recycling: New and emerging standards will likely mandate much lower thresholds for contaminants in digestate and compost. Councils must anticipate not just current, but future, compliance obligations to avoid costly retrofits and reputational harm.

Modern Anaerobic Digestion Food Waste Solutions for Councils

Advantages of Non-Destructive Food Waste Depackagers

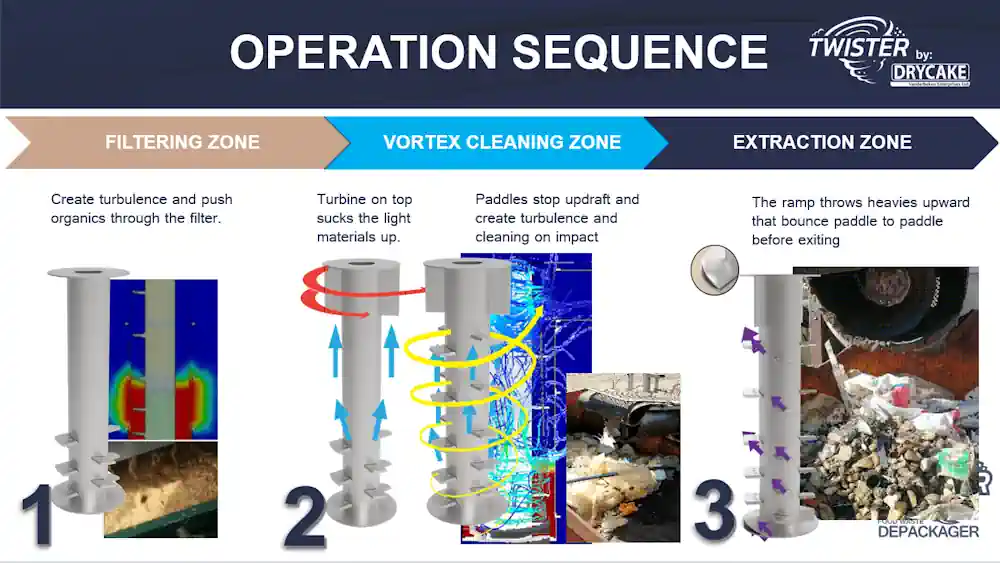

Recent technology breakthroughs have yielded advanced non-destructive depackagers designed specifically for anaerobic digestion food waste streams. These systems employ centrifugal force and targeted separation methods, rather than indiscriminate size reduction, to open and empty food packaging. This preserves the integrity of plastics, enabling easier recycling and minimizing the creation of harmful microplastics.

- Centrifugal force vs. size reduction: By spinning or mechanically “teasing” food from its container, these machines perform a cleaner, more complete separation. Food organics exit almost free of packaging, while intact bottles, wrappers, or cans are collected for downstream recycling or energy recovery.

- Preserving plastics for further waste recycling or energy recovery: When plastics remain intact, they retain material value for recycling (e.g. as feedstock for new packaging or products) or can be redirected to energy from waste incineration, maximizing the energy yield per tonne of food waste recycling.

- Reducing long-term environmental risks: With fewer microplastics and heavy metals released into anaerobic digestate or compost, councils meet stricter standards and safeguard soil and water health—a true win-win for both today’s and tomorrow’s communities.

“Modern depackagers, like the Drycake Twister, are engineered to keep microplastics out of the food chain by preserving packaging integrity during anaerobic digestion food waste processing.”

People Also Ask: Anaerobic Digestion Food Waste Insights

Do anaerobic digestion facilities accept this waste?

Yes, anaerobic digestion is specifically designed to receive and process food waste and other organic material. Anaerobic digesters operate by accepting controlled loads of organic matter, such as food scraps, agricultural residues, and some animal bedding, where the digestion process produces biogas, which can be used for heat and power generation, and digestate for agriculture.

However, not all anaerobic digestion facilities will accept food waste. First, they must be licensed “permitted” by the UK Environment Agency, and as this is an onerous process compared to accepting farm wastes only, many on-farm biogas plants cannot accept food waste.

Is anaerobic digestion better than composting?

Anaerobic digestion and composting are both sustainable methods of treating food and organic waste, but they serve different purposes.

AD captures valuable biogas to produce renewable electricity, heat and power, or after quality-controlled purification, inject into the gas grid, while composting simply transforms waste into organic soil conditioner without generating energy.

For councils looking to generate renewable energy and reduce their carbon footprint, AD often offers greater benefits—provided appropriate contamination controls are in place.

Only anaerobic digestion holds the prospect of being carbon negative – something not possible for composting.

Is anaerobic digestion recycling or recovery?

Anaerobic digestion is considered both a recycling and a recovery process. It recycles the organic fraction of food waste into biogas and nutrient-rich digestate (used as fertilizer), but it can also be classified as recovery when the primary focus is on energy generation.

The line between recycling and recovery depends on whether the end product (digestate) is used beneficially on land and how much energy is recovered relative to the original calorific value.

This dynamic documentary takes viewers through the food waste transformation: from household collection bins, through advanced depackaging and the anaerobic digestion process, all the way to renewable energy generation and recycled byproducts.

Key Takeaways on Anaerobic Digestion, Food Waste and the Microplastics Challenge

- Advanced depackaging technology is critical to prevent microplastic contamination during anaerobic digestion food waste processing

- Councils must balance economic pressures against environmental consequences

- Properly separated food waste has strong potential to help meet climate targets, but only if long-term impacts are addressed

FAQs: Anaerobic Digestion Food Waste—Your Critical Questions Answered

- What types of food waste are suitable for anaerobic digestion?

Most food waste—including cooked leftovers, fruit and vegetable peelings, expired supermarket products, and even meat, dairy, and bakery waste—can be broken down by anaerobic digestion. Non-food contaminants, particularly plastics and metals, must be minimized before processing to avoid damaging the digester and contaminating outputs. - How can local authorities ensure safe processing of food waste?

Councils should specify in their contracts that only advanced, non-destructive depackagers—or food waste collected directly from the consumer without residual packaging—are to be used for anaerobic digestion food waste processing. Regular audits and testing for microplastic and heavy metal residues in both the process and outputs are essential to prevent environmental harm. - What are the main outputs of the anaerobic digestion food waste process?

The two key outputs are biogas (a mix of methane and carbon dioxide used for heat and power, or upgraded for injection into the natural gas grid) and digestate, which is a nutrient-rich biofertiliser suitable for agricultural land—assuming it’s free of plastic contamination. - How do plastics impact the value of the final digestate or compost?

Plastic contamination, especially microplastics, can dramatically reduce the value and marketability of digestate or compost. Contaminated products may be rejected for agricultural use, restricting outlets and potentially turning a valuable by-product into expensive waste. Strict separation standards and modern depackaging equipment are thus essential to preserve digestate quality.

Conclusion: Balancing Today’s Food Waste Demands with Tomorrow’s Environmental Care

Councils must act decisively to unlock the energy in food waste—while ensuring their choices don’t sow microplastic risks for future generations.

Learn More about Clean, Efficient Anaerobic Digestion Food Waste Solutions

Ready to help your council lead the way with clean, responsible food waste recycling? For information on the Drycake Twister food waste separation depackagers that separate food organics cleanly while preserving the reject materials for recycling or energy extraction, visit https://twisterseparator.com

Sources

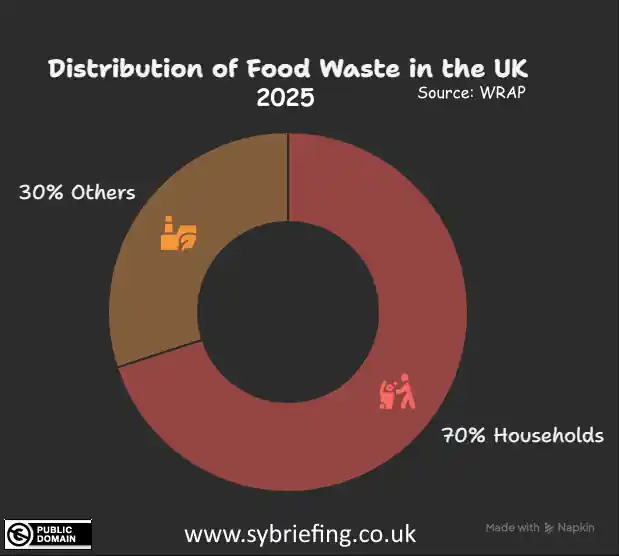

- WRAP: Anaerobic Digestion Guidance

- UK Government: Environment Act 2021

- LetsRecycle.com – 2026 Food Waste Collections

- REA: Anaerobic Digestion Explained

- Drycake Twister – Advanced Food Waste Separation Solutions

To further explore the benefits and processes of anaerobic digestion for food waste, consider the following resources:

- The U.S. Environmental Protection Agency’s article, “Environmental Benefits of Anaerobic Digestion (AD),” outlines how anaerobic digestion diverts organic materials from landfills, generates renewable energy, and produces nutrient-rich digestate that enhances soil health.

- BioteCH4’s piece, “What Is Anaerobic Digestion of Food Waste?,” details the transformation of food waste into biogas and biofertilizer, emphasizing the environmental and economic advantages of this sustainable waste management method.

If you’re serious about understanding and implementing anaerobic digestion for food waste, these resources will provide you with comprehensive insights and practical guidance